BIOPAK

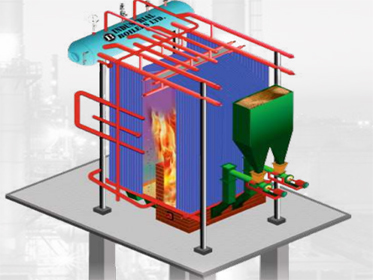

THE BIOMASS FIRED BOILER

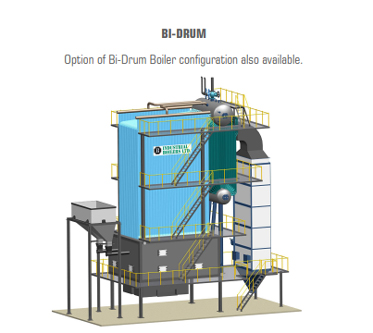

THE BIOMASS FIRED POWER BOILER

•Rice Husk / Saw Dust / Ground Nut Shell / Cashew Shell

•Rice Husk / Mustard Straw / Cotton Stalk

•Bagasse / Palm Fibre

- Over-bed FBC / Reciprocating Grate

- Reciprocating Grate / Water Cooled Vibrating Grate

- Travelling Grate / Water Cooled Vibrating Grate

At start-up the water circulation starts very quickly because there are short overflow distances from downcomer to heating surface on water side. Due to these short distances all water filed tubes reach saturation temperature very quickly at start-up. Dangerous material stress caused by different thermal expansion does not occur.

A generous combustion volume above the Fluidised bed ensures complete combustion of the fuel, leading to low unburnt and high combustion efficiency. The combustion space is strategically expanded to reduce flame velocity and allow radiation to impart its energy to the water walls.

Unlike Bi-Drum boilers where the downcomer tubes also act as riser tubes at high load, Bio-M has separate and distinct downcomers with large diameter. Steam bubbles forming at pressure fluctuations and high load change velocities cannot endanger the water circulation.

The admissible temperature variation gradient is significantly higher due to welded construction, leading to a quick start-up. Welded tubes have always been more reliable than expanded tubes.

The water level in the drum keeps calm compared to Bi-Drum boiler since steam-water mixture pre-separates externally before entering the Drum.

Biomedical waste Rotary Incinerators